Mastic duct sealer can be applied to the non-metallic part of ductboard. Mastic is a high-quality sealant that is often used in HVAC systems to seal joints and seams against air leakage. It is designed to adhere to a wide variety of materials, including the fiberglass and foil-faced surfaces of ductboard.

Here’s how to apply it:

1. Clean the Surface: Make sure the surface of the ductboard is clean and dry. Remove any dust, dirt, or grease that could prevent the mastic from adhering properly.

2. Apply Mastic: Using a brush or gloved hand, apply a generous layer of mastic to the ductboard. Make sure to cover all seams and joints.

3. Let it Dry: Allow the mastic to dry completely. This could take several hours or even overnight, depending on the thickness of the application and the temperature and humidity of the environment.

4. Inspect the Seal: Once the mastic has dried, check to make sure the seal is complete. If there are any gaps or cracks, apply another layer of mastic and let it dry.

Remember, always follow the manufacturer’s instructions when using mastic or any other sealant.

you can apply the mastic to both the 2″ side of the ductboard and the side of the furnace before joining them together. However, you need to make sure it’s applied carefully and evenly to get a good seal.

Here’s a simple step-by-step guide:

1. Clean the Surfaces: Make sure both surfaces (the ductboard and the furnace) are clean and free of dust, dirt or grease.

2. Apply the Mastic: Use a brush to apply a thick, even layer of mastic on both surfaces. Make sure you cover the entire surface area that will be joined.

3. Join the Surfaces: Press the ductboard against the furnace firmly. This ensures that the mastic spreads out evenly and fills any gaps or irregularities between the two surfaces.

4. Secure the Joint: If necessary, you can use duct tape or mechanical fasteners to hold the ductboard in place while the mastic dries. Do not rely on these for the seal – they just provide extra support.

5. Let it Dry: Leave the mastic to dry completely. This can take several hours or even overnight, depending on the conditions.

6. Check the Seal: Once the mastic is dry, check the seal. If there are any gaps or cracks, apply another layer of mastic.

Remember, always follow the manufacturer’s instructions when using mastic. And keep in mind that mastic should not be used in areas where it will be exposed to high heat, such as near the heat exchanger or flue pipe of a furnace.

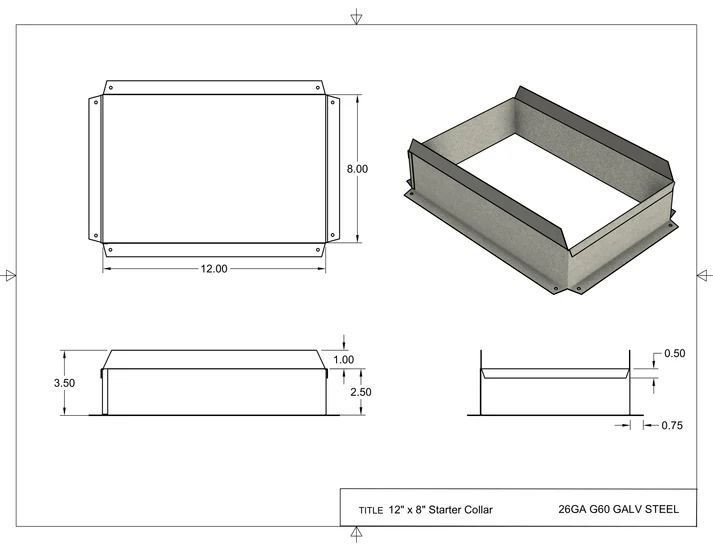

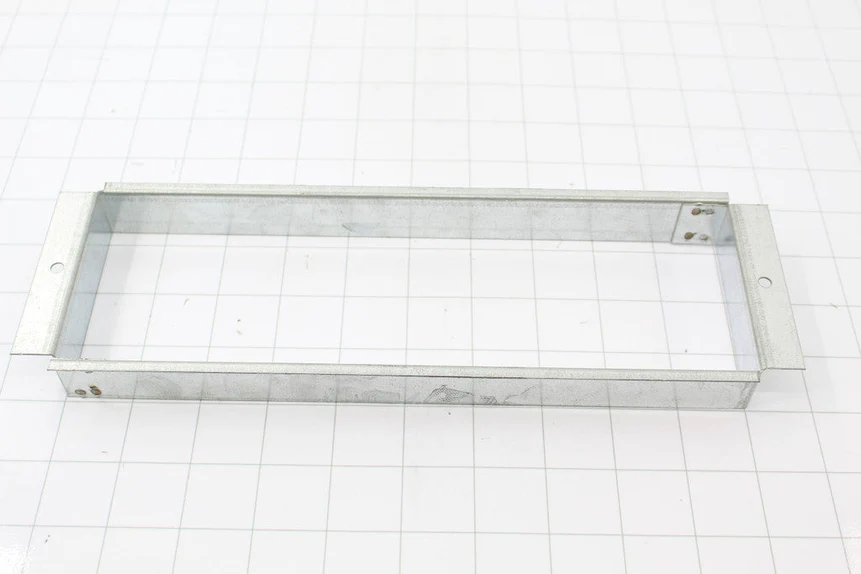

While mastic is an excellent sealing material, it’s not typically used as a structural component. The primary function of a duct collar is to provide a secure, mechanical connection between the duct and the furnace, while the mastic provides an airtight seal.

Without a duct collar, the mastic alone may not be sufficient to hold the duct in place and withstand the pressure differences that occur during the operation of the HVAC system, especially in the long term.

So while you might be able to get away without using a duct collar in the short term, it is highly recommended to use one for a long-lasting and secure connection. After the collar is installed, mastic can then be applied around the connection to ensure an airtight seal.